We provide 4 major groups of rules:

1. General Cutting Rules

There are 6 sub-types in this group:

Type A,B,C,D,S and H

| Type A | Type B | |

|---|---|---|

| Bevel Shape | CB-Center Bevel | LCB-Long Center Bevel |

| Thickness | 0.71mm(2PT),1.06mm(3PT),1.42mm(4PT) | Height | 22.8mm-30.0mm |

| Bevel Angel | <42, <52 | <42/7 , <52/7 |

| Hardness-Tip | HS48, HS52, HS55, HS60 | |

| Application | To cut business card,cardeboard,etc. | |

| Type C | Type D | |

|---|---|---|

| Bevel Shape | CB-Center Bevel | LCB-Long Center Bevel |

| Thickness | 0.71mm(2PT),1.06mm(3PT),1.42mm(4PT) | Height | 22.8mm-30.0mm |

| Bevel Angel | <42, <52 | <42/7 , <52/7 |

| Hardness-Body | HS48,HS52,HS55 | |

| Hardness-Tip | HS76(HV630) | |

| Application | To cut business card,cardeboard,thin corrugated paper | Comparing Type C & D can cut thicker/ harder materials, such like corrugated paper, thin asbestos board, carban fabric board, plastic board... |

| Type S | ||

|---|---|---|

| Bevel Shape | SB, Side Bevel | LCB, Long Side Bevel |

| Thickness | 0.71mm(2PT),1.06mm(3PT) | Height | 22.8mm-50.0mm |

| Bevel Angel | <42, <52 | <52/11 |

| Hardness-Body | HS48,HS52 | |

| Hardness-Tip | HS76(HV630) | |

| Application | To cut rubber and plastic | |

| Type H | ||

|---|---|---|

| Bevel Shape | CB, Center Bevel | LCB, Long Center Bevel |

| Thickness | 0.71mm(2PT),1.06mm(3PT) | Height | 30mm-50mm |

| Bevel Angel | <42, <52 | <52/7 |

| Hardness-Body | HS48,HS52 | |

| Hardness-Tip | HS76(HV630) | |

| Application | To cut thick foam sheet, copper paper,leather,plastic,etc. | |

2. Creasing Rules

We provide three different edge shapes for creasing rules

| Creasing Rules(Type E) | |||

|---|---|---|---|

| Thickness | 0.71mm/1.06mm/1.42mm | Height | 22.6mm-24.35mm |

| Edge Shape | DR ,Double Round | SR, Single Round | Special Facet |

| Hardness-Body | HS52,HS55 | ||

| Application | Double Round is easily used and suitable for all applications | The flat edge makes the creasing rule more stable in cutting dies | with the smaller tip (0.35mm-0.53mm),it is used for creasing finer or sophisticated folding works |

3. Label Rules

The ground bevel edge with very thin body is the best choice for making complicated cutting dies and to cut special thin materials

| Label Rules (Type L) | |

|---|---|

| Thickness | 0.45mm/0.53mm | Height | 7mm-12mm |

| Bevel Angel | <42 , <52 |

| Hardness-Body | HS52,HS55 |

| Hardness-Tip | Without hardened tip: same with body hardness With hardened tip: HS72 (HV580) |

| Application | To cut sticker, thin plastic.Polyster fiber label,etc. With hardened edge can cut thicker/ harder materials and can make the rules longer lifetime |

4. Perforating Rules

We provide various size of perforating rules to meet different needs

| Perforating Rules | |

|---|---|

| Thickness | 0.71mm | Height | 23.60mm-23.80mm |

| Bevel Angel | <42 , <52 |

| Hardness-Body | HS52 |

| Hardness-Tip | without hardened tip:same with body hardness with hardened tip:HS72(HV630) |

| Tooth-Sizes | 1x2 2x1 2x2 3x1 3x3 |

| Application | To make tearing line or folding line on card , corrugated paper, label,etc. |

| Type | Tooth | Gap | Thickness | Depth | Height |

|---|---|---|---|---|---|

| 1x1 | 1.0 | 1.0 | 0.71 | 2.5 | 23.6/23.8 |

| 2X1 | 2.0 | 1.0 | 0.71 | 2.5 | 23.6/23.8 |

| 2x2 | 2.0 | 2.0 | 0.71 | 2.5 | 23.6/23.8 |

| 3x1 | 3.0 | 1.0 | 0.71 | 2.5 | 23.6/23.8 |

| 3x3 | 3.0 | 3.0 | 0.71 | 2.5 | 23.6/23.8 |

Use of Best Raw Material

Best products only from best raw materials. Hung-Shuh Co. insists to use the first level steel strips provided by the Sumitomo Metal Industries, Ltd from Japan to assure our customers receive only best products.

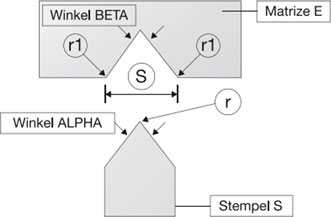

We follow the Germany Cutting Rule Manufacturing Standards:

1. Flexibility

| Thickness | Hardness | Beta | R1 | s | No. | Alpha | R | No. |

|---|---|---|---|---|---|---|---|---|

| 0.71 | H2/HF | 50* | 1 | 6 | E1 | 40* | 0.50 | S1 |

| 0.71 | H3 | 60* | 1 | 6 | E2 | 40* | 0.50 | S1 |

| 1.05 | H2 | 60* | 1 | 6 | E2 | 40* | 0.50 | S1 |

| 1.05 | H3 | 70* | 1 | 10 | E3 | 40* | 0.75 | S2 |

| 1.42 | H2 | 70* | 1 | 10 | E3 | 40* | 0.75 | S2 |

| 1.42 | H3 | 100* | 1 | 10 | E4 | 40* | 0.75 | S2 |

Above perimeter Explanations

| Hardness Perimeter | Tip Hardening Process (With high frequency) |

Hardness-Body | Hardness-tip |

|---|---|---|---|

| H2/HF | Yes | HRC34-38/HV340-380 | HRC51-56/HV520-620 |

| H3/HF | Yes | HRC40-46/HV400-460 | HRC51-56/HV520-620 |

| H2 | No | HRC34-38/HV340-380 | |

| H3 | NO | HRC40-46/HV400-460 | |

| H4 | No | HRC49-53/HV520-580 |

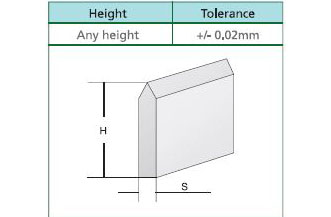

2. Thickness Tolerance

(Thickness=S, accourding to DIN 1544P)

| Thickness | Tolerance |

|---|---|

| 0.45mm /1.27pt | +/-0.015mm |

| 0.53mm /1.5pt | +/-0.015mm |

| 0.71mm /2pt | +/-0.015mm |

| 1.06mm /3pt | +/-0.020mm |

| 1.42mm /4pt | +/-0.025mm |

7. Hardness Tolerance: HS +/-2